Experimental Machine, Inc. | New Freedom, Pennsylvania

At Experimental Machine, Inc. (EMI), precision is not a single process - it is a fully integrated manufacturing system. From complex 5 Axis Machining to mission-critical assembly and industry-leading inspection, our capabilities are designed to support the most demanding aerospace, defense, and advanced commercial applications.

By centralizing machining, assembly, and quality under one roof, EMI delivers reduced lead times, absolute traceability, and uncompromising performanceómeeting and exceeding the expectations of 2026ís most rigorous industry standards.

Explore our three core areas of capability below.

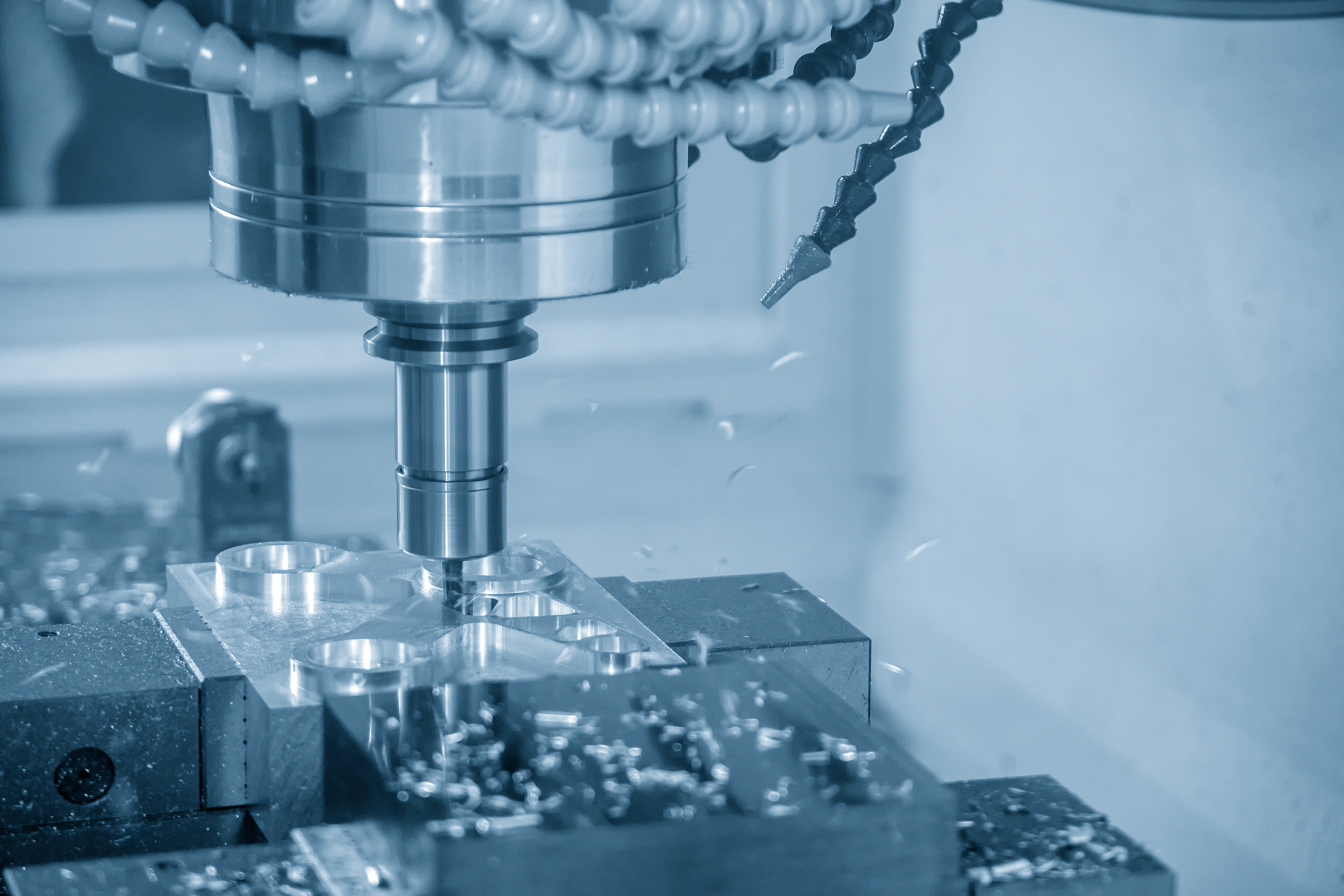

EMIís 5 Axis CNC machining capability unlocks true design freedom for complex, high-precision components. Our advanced systems allow simultaneous movement across 5 axes, enabling us to machine intricate geometries in a single setup with exceptional accuracy and surface finish.

Housing machining and assembly within the same facility ensures design intent is preserved, communication is seamless, and sensitive components remain secure. Our ITAR-registered environment supports strict documentation, traceability, and regulatory compliance while reducing supply-chain risk and program delays.

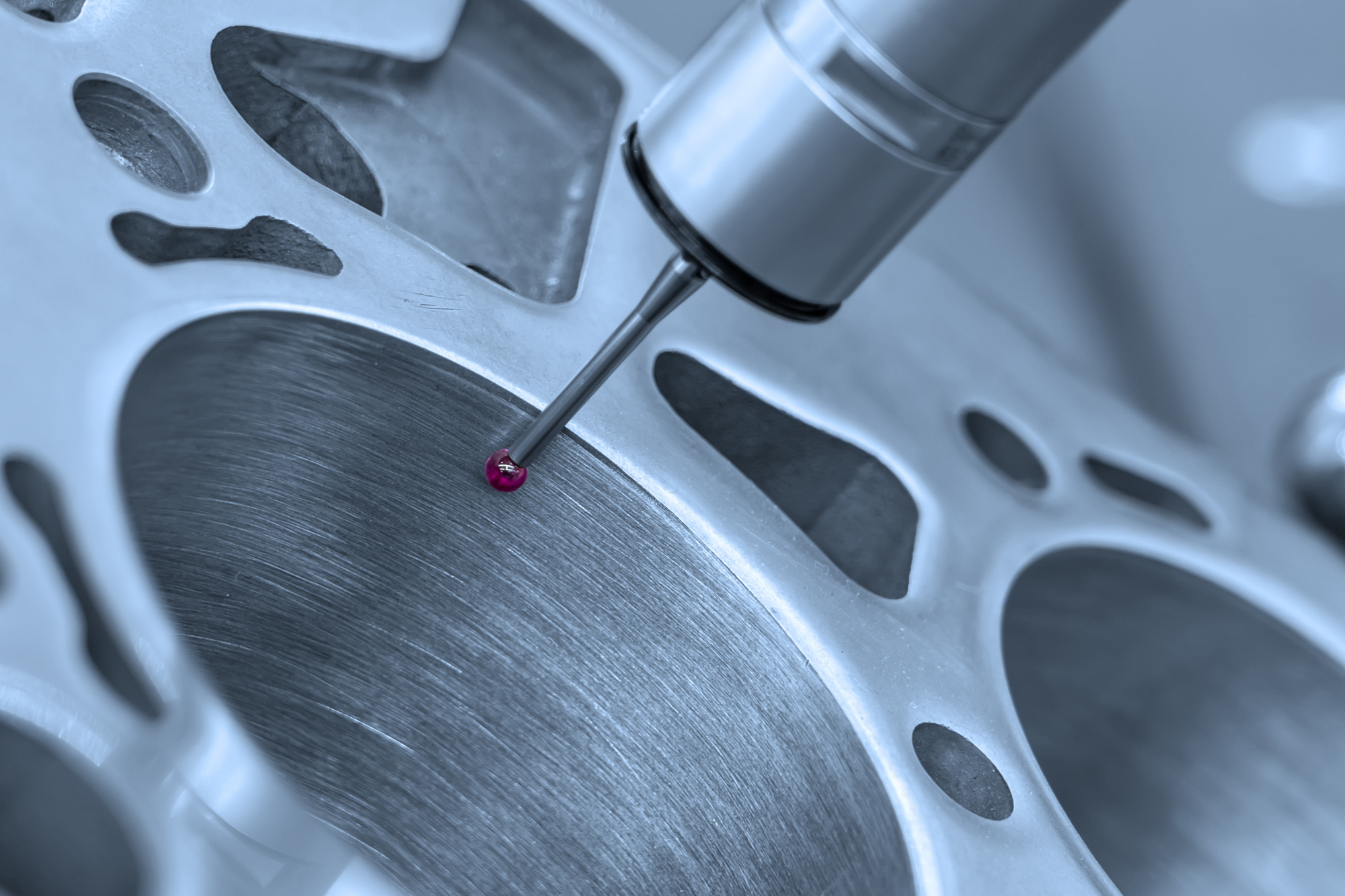

EMIís commitment to quality is backed by industry-leading metrology technology and a culture of precision verification. Our inspection department employs advanced CMM and 3D laser scanning systems to validate complex geometries, tight tolerances, and critical features with absolute confidence.

Experimental Machine, Inc. maintains a modern, well-equipped facility to support precision machining, inspection, and complex manufacturing requirements. Our investment in advanced equipment allows us to deliver tight tolerances, repeatability, and efficient production.

CAGE CODE: 0NAP8

UEI: NN75TNQACFU5

Copyright 2026 - All Rights Reserved. | Site Powered by Sunken Treasure Design